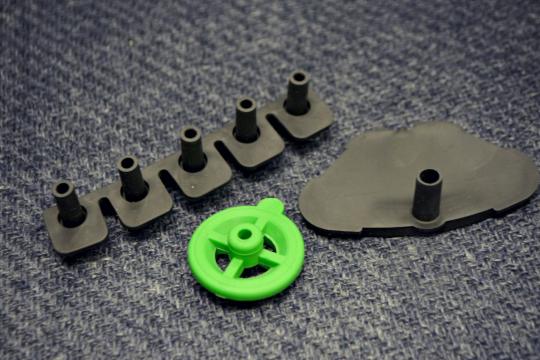

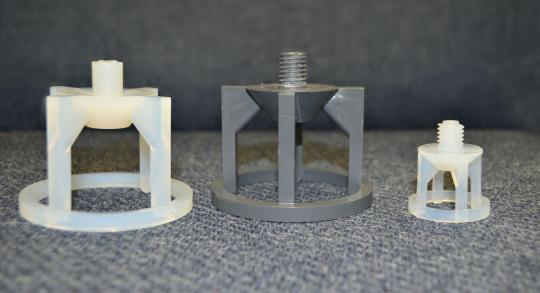

Unique -- unique is the word used to describe Pasco Tool and Plastics, Inc.’s injection molding process. Injection molding enables us to champion the creation and implementation of the full product life cycle, customer concept to full production. Injection molding is a manufacturing process that produces plastic or metal parts by casting them into custom molds. Here at Pasco Tool and Plastics, Inc., we offer customized injection molding processes to deliver distinct tooled parts at an equitable cost. And that is why we say we are unique. We utilize the latest technology in processing controls to ensure quality and consistency. We provide end-to-end design services to ensure that parts and molds are the highest quality possible.

Our growing plastics department features highly adaptable machinery. With molding capacities ranging from 6 tons to 433 tons, tie bar spacing from 3" square to 36" square and shot sizes from 0.13 ounces to 30.6 ounces, Pasco Tool & Plastics is well equipped for in-house sampling or production runs of any quantity.